From: CRI Online/China.org.cn — First in China! SNTO’s 18 Automatic Production Lines of Aluminum Formwork Put into Production

Recently, 18 automatic production lines of aluminum formwork independently developed by SNTO have been officially put into production. First seen in China, they are the automatic production lines of aluminum formwork with the highest degree of automation and the most complete integrated process, reaching an automation rate of 78%. As a benchmark project of the automatic production line development in the industry, this project has led the direction of upgrading and transformation of China’s aluminum formwork industry to intelligent manufacturing.

SNTO, headquartered in Changsha, Hunan Province, is one of the leaders in the aluminum processing industry in China. Since its establishment in 2003, SNTO has been committed to promoting the R&D and innovation of the efficient application of aluminum alloy. Since September 2020, its equipment R&D and design team has invested more than RMB 40 million to continuously promote the upgrading of automatic production lines through innovation and has successively realized the innovation and upgrading from flat truss and vertical truss to the gantry structure. At present, 18 independently developed automatic production lines for aluminum formwork have realized stable mass production, with a product qualification rate of 98.5%, a delivery time more than twice faster than that of similar production lines of peers, and a monthly production capacity of 100,000 square meters.

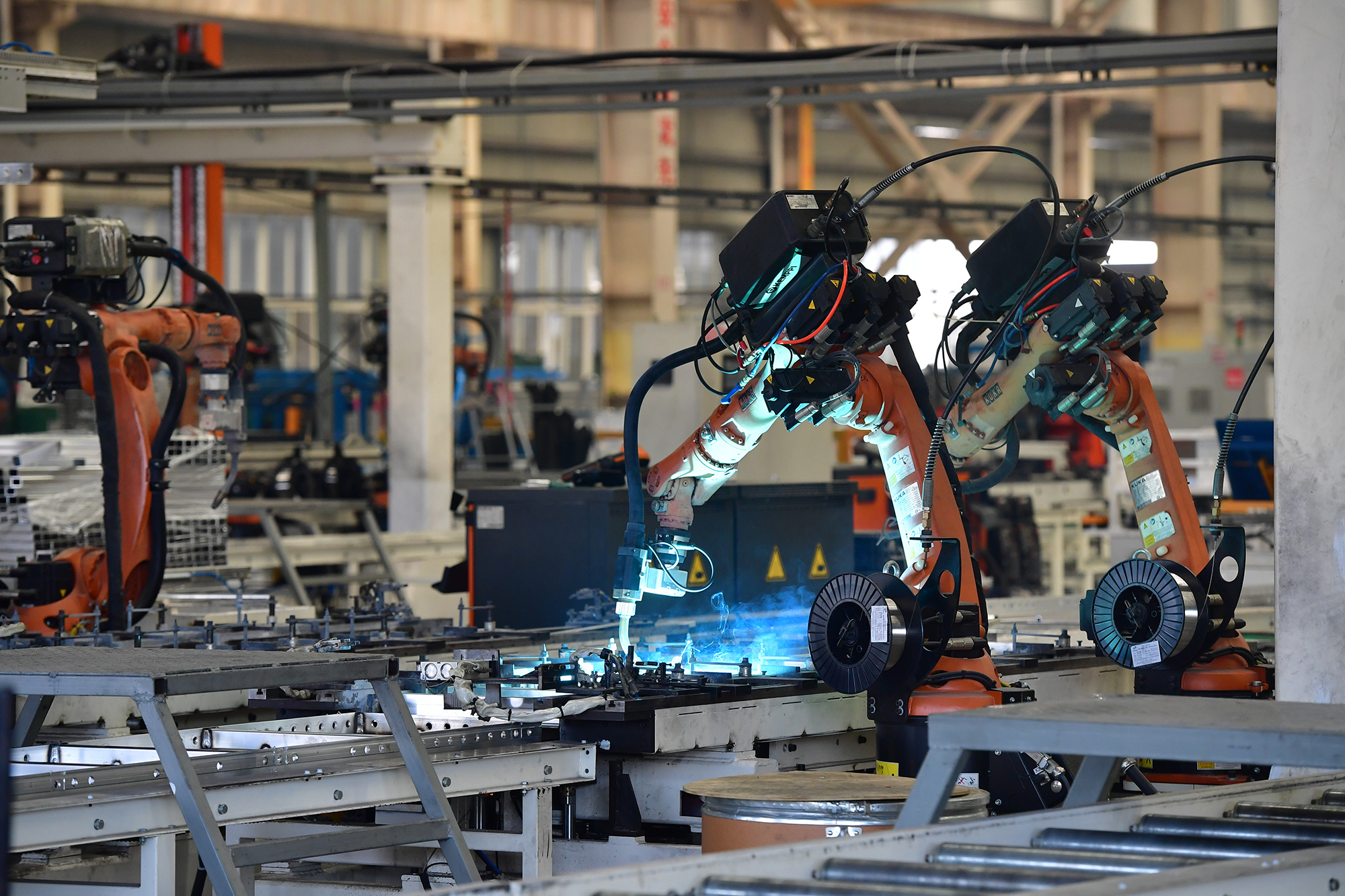

In the past, the manufacturing and processing of aluminum formwork were generally completed through a complicated process including linear saw, single-row punching, groove milling of milling machine, and manual welding. This process has high labor intensity, low processing efficiency, and high professional requirements. The technical level and operation specifications of welding operators have a great impact on product quality. At the same time, due to the harm of arc and welding smoke to health, fewer and fewer workers choose to engage in welding, resulting in increased production costs.

As the first fully automatic production line of aluminum formwork that has realized mass production in China, this production line has realized the automation control in the whole process of the processing and production of aluminum formwork from material loading, saw cutting, punching, groove milling, rib milling, and automatic welding to the stacking of finished products, with the advantages of high processing accuracy, high automation degree, and simple and convenient operation. Taking the wall formwork as an example, the workload of manual welding by 10 persons in the past can be completed by only one person, which improves the production efficiency by nearly 10 times. There are no more than 2 general workers in the whole production line. It can reduce the operation risk of welding operators and effectively protect the health of employees.

In April this year, the first-in-China flexible production line for non-standard parts of aluminum formwork built by SNTO started mass production, further meeting the diversified demands of future market changes. On this basis, the SNTO Aluminum Formwork R&D Team will continue to promote the research and development of the sorting-free assembly system this year, so as to realize zero-defect delivery of the aluminum formwork. SNTO will continue to strive to build an Industrial 4.0 green factory with high level, high efficiency, high quality, low cost, and low pollution, so as to realize the automation, informatization, integration, visualization, and modularization of production.