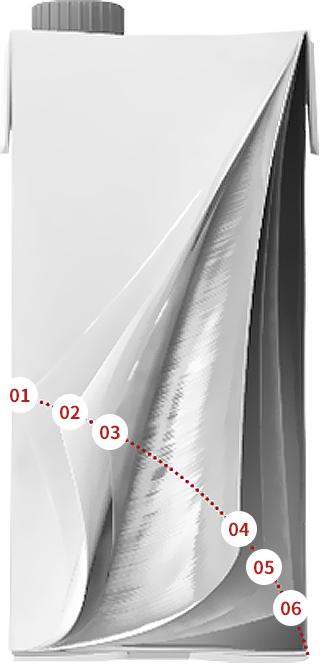

Forth layer — Aluminum foil:

The core layer of food preservation.

Forth layer — Aluminum foil:

The core layer of food preservation.

For milk, tea drinks, fruit and vegetable juice packaging, etc. The application of aluminum foil in such products effectively extends products shelf life and freshness time, so that people can drink fresh beverages at home.

For retort pouch food, nuts, snack, candy, seasoning, betel nut, etc. Aluminum foil has strong plasticity and exquisite printing effect, which can improve our life quality.

For high-end tobacco paper backing and cardboard. Aluminum foil, with its superior barrier, moisture and mildew proofing properties, prolongs cigarettes storage time.

high-end exquisite appearance, improved added value of food.

easy to print and form, high lamination efficiency.

strong barrier and shading, reducing preservative addition quantity and prolonging freshness lifetime.

Only 1.5g aluminum foil is needed in a 28g composite packaging which could store and transport 1L milk over months without refrigerating.

integrate expert resources such as design, packaging, food, scientific research institutions, and provide solution to customers problem.

provide lean management guidance to help customers reduce cost and increase efficiency

shoot aluminum foil products advantages video and user manual, so that customers can experience the one-stop service of purchasing SNTO aluminum foil.

Standardization of products: Standard specifications ensure fast delivery. Customers do not need to stock separately. Zero stock could significantly reduce capital occupation.

Efficient logistics: Combine self-operated logistics with internationally well-known logistics to ensure safe and punctual delivery by real-time monitoring during transportation.

Stable quality: 6mic aluminum foil has better flatness, less pinhole(quantity ≤ 200 pcs/m2)

and good performance (elongation ≥ 2%) which is suitable for 800 meters/min high speed production.

We achieved 43 million meters continuous production without web breaking and improved composite efficiency by more than 2 times.

Standardized management: SNTO self-produced continuous casting coil are used to ensure quality from source.

With "five standards and ten steps" zero defect quality management mode,

we realized standardized management of the whole production process.

The short-process continuous casting coil production process

completely replaces direct casting,which protected green

mountains and clear water with less energy consumption

of per ton of aluminum and fewer carbon emissions.